Custom Pipe Fittings Manufacture

Since 2000

Specialized in Pipeline Solutions for Over 20 Years.

21760m2

Factory area

150items

high-speed extruded and injection lines

200000CBM

Annual production capacity of MBBR

120+

Cooperating countries

Production Process

HDPE Pipe Fittings Design & manufacturing

step 1

Raw Material Preparation

High-quality 100% virgin polyethylene pellets, typically imported from Northern Europe, are selected for their durability. These materials are precisely mixed using fully automated feeders to ensure accurate ratios and continuous supply.

step 2

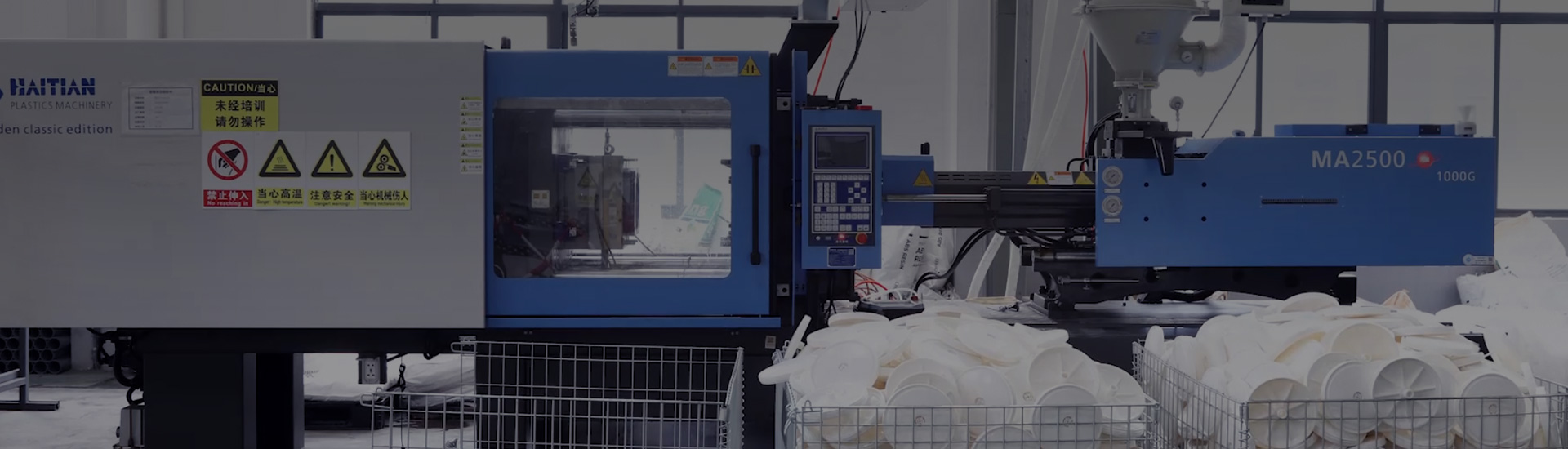

Injection Molding

The mixed materials are fed into SOUND UN Series injection molding machines, which use high-efficiency servo-driven technology to inject the molten HDPE into precision molds, forming the desired pipe fitting shapes.

step 3

Cooling and Demolding

The molded pipe fittings are cooled using water or air cooling systems to stabilize their dimensions and shape. Once cooled, the fittings are automatically demolded.

step 4

Machining and Finishing

After demolding, the fittings undergo necessary machining and finishing using CNC precision lathes and other equipment to ensure each product meets the required precision and surface quality standards.

step 5

Quality Inspection and Packaging

All fittings are subjected to rigorous quality inspections, including dimensional checks, pressure tests, and impact resistance tests, to ensure they meet quality standards. Approved products are then sorted, packaged, and shipped according to customer orders.

Manufacturing Equipment

SOUND UN Series Injection Molding Machines

Manufacturing Equipment

Fully Automatic Material Feeders

Manufacturing Equipment

CNC Precision Lathes

Manufacturing Equipment

Imported Raw Materials from Northern Europe

Manufacturing Equipment

Precision Machined Molds

Manufacturing Equipment

Testing Workshop

Industry Recognition

Trusted Certification

- Name:

- Pan Yan

- Tel:

86-15268186595

0-571-89332538

- Email:

- fitting@welping.cn

- WhatsApp:

- https://wa.me/8613185061581

- Address:

- Room 1904 Building 1, Taifu Plaza, No. 1 Tonghui Middle Road, Xiaoshan District, Hangzhou

Please Send Your Message to Us

Free Pipe System Design Consultation: Receive a customized pipe system design tailored to your project needs.

Sample Experience: Obtain pipe fitting samples to experience the quality and performance of our products firsthand.

Project Installation Support: Access detailed installation guidance to ensure the smooth execution of your project.

Customized Solutions: Get bespoke pipe fitting solutions tailored to your specific requirements.

Industry Trend Report: Stay ahead with the latest insights into the pipe fittings industry to gain a competitive edge.

Reach out to us now to learn more about our products and services and start your successful project!

- Tel

- *Title

- *Content